Top 5 Test Tools for Fiber Optic Technicians

In the dynamic world of fiber optics, ensuring the reliability and performance of networks is of utmost importance. Whether you're installing, maintaining, or troubleshooting fiber optic infrastructure, having the right tools at your disposal is an absolute priority. In this blog, we'll explore the top 5 test tools that allow fiber optic technicians to optimize network performance, troubleshoot issues with precision, and ensure the integrity of critical communications infrastructure.

1. Optical Power Meter/Light Source

A power meter and light source are both essential tools used by fiber optic technicians to measure and verify the performance of fiber optic links. The power meter is designed to accurately measure the optical power level of signals transmitted through the fiber optic cables, while the light source generates a stable and calibrated light signal that is transmitted through the fiber. Together, they form a powerful testing duo, with the light source emitting a known power level of light into the fiber and the power meter capturing and quantifying the amount of light energy present in the fiber. This tandem operation allows technicians to conduct precise power loss measurements, identify faulty components or connections within the network, and verify the integrity of fiber optic links. By providing accurate and reliable measurements of optical power, the power meter and light source enable technicians to maintain the integrity and performance of fiber optic networks, ensuring optimal signal transmission and minimizing the risk of network downtime. Their versatility and ease of use make them invaluable tools for fiber optic technicians, empowering them to troubleshoot network issues, conduct routine inspections, and optimize network performance with confidence and efficiency.

2. Optical Time-Domain Reflectometer (OTDR)

An Optical Time-Domain Reflectometer (OTDR) is a specialized tool used in fiber optic networks for characterizing and troubleshooting optical fibers. It operates on the principle of sending short pulses of light into the fiber and measuring the reflections caused by variations in the fiber's properties. By analyzing these signals, an OTDR can precisely determine fiber length, attenuation, splice loss, and identify any faults or anomalies along the fiber path. Additionally, they show connection points, which can also have loss. All in all, an OTDR provides a comprehensive "snapshot" of the fiber optic cable's condition, enabling technicians to assess its health and performance with unparalleled accuracy.

One of the key features of an OTDR is its ability to measure the optical loss and reflectance at various points along the fiber. This information is essential for evaluating the quality of fiber optic installations, identifying potential sources of signal degradation, and optimizing network performance. Additionally, OTDRs offer advanced analysis capabilities such as event detection, which allows technicians to pinpoint the location and characteristics of fiber optic events such as splices, bends, breaks, or other anomalies. This granular level of detail enables technicians to quickly diagnose network issues and implement targeted solutions, minimizing downtime and ensuring optimal network performance.

Another important feature of OTDRs is their versatility and portability, making them suitable for a wide range of applications in fiber optic testing and maintenance. Whether deployed in the field for troubleshooting and maintenance tasks or used in the laboratory for network characterization and quality assurance, OTDRs offer robust performance and intuitive operation. With their user-friendly interfaces and comprehensive reporting capabilities, OTDRs empower technicians to efficiently analyze and document fiber optic networks, facilitating timely decision-making and ensuring the reliability and integrity of critical communications infrastructure. For a more in depth and detailed review of the OTDR, you can read our blog here!

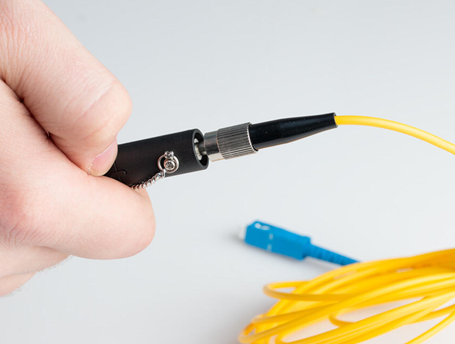

3. Visual Fault Locator (VFL)

A visual fault locator (VFL) is a compact and portable tool used by fiber optic technicians to quickly and effectively identify faults, breaks, bends, or other discontinuities in fiber optic cables. It operates by emitting a bright, visible light into the fiber, which illuminates any points of signal leakage along the cable's length. This light leakage is visible to the naked eye and appears as a glowing or flashing light, making it easy for technicians to visually inspect the fiber optic cable for defects. VFLs are commonly used in conjunction with patch cords or adapter caps to facilitate easy connection to the fiber optic cable. They are particularly useful for troubleshooting and maintenance tasks, allowing technicians to rapidly pinpoint the location of faults and expedite repair efforts, ultimately minimizing downtime and optimizing network reliability.

The use of a visual fault locator is straightforward and intuitive. To use a VFL, technicians simply connect the VFL to one end of the fiber optic cable and activate the light source. The bright, visible light emitted by the VFL travels through the fiber optic cable, illuminating any points of signal leakage or breaks along the cable's length. Technicians can then visually inspect the cable for glowing or flashing light, which indicates the presence of a fault. By moving the VFL along the length of the cable and observing any changes in the light pattern, technicians can precisely locate the fault and determine the extent of the damage. Once the fault is identified, technicians can take appropriate measures to repair or replace the affected portion of the cable, restoring network connectivity and ensuring optimal performance. Keep in mind that VFLs are used with colored jackets, such as yellow or blue, since they do not work with black jackets.

A visual fault locator is valuable due to its effectiveness in quickly identifying faults and defects in fiber optic cables. Unlike other diagnostic tools such as OTDRs, which provide detailed analysis of the fiber's characteristics but may require more time and expertise to operate, VFLs offer a simple and cost-effective solution for rapid fault detection. This makes them invaluable for troubleshooting network outages, conducting routine inspections, and verifying the integrity of fiber optic links. By enabling technicians to quickly locate and address faults in the fiber optic infrastructure, VFLs help minimize downtime, reduce repair costs, and ensure the reliability and performance of critical communications networks.

4. Fiber Optic Inspection Microscope

A fiber optic inspection microscope is a specialized tool used by fiber optic technicians to visually inspect the end-faces of fiber optic connectors for dirt, debris, scratches, or other defects that may degrade signal quality or cause network performance issues. The microscope typically consists of a high-quality optical lens system, a light source, and a viewing screen/eyepiece for magnified inspection.

To use a fiber optic inspection microscope, technicians simply connect the microscope to the end-face of the fiber optic connector and illuminate the connector with the built-in light source. The optical lens system magnifies the end-face of the connector, allowing technicians to observe even the smallest imperfections with great detail. By conducting thorough inspections of fiber optic connectors, technicians can ensure the cleanliness and quality of connections, identify potential sources of signal degradation, and mitigate the risk of network downtime or transmission errors. For safety measures, make sure to only use the microscope on dark fiber, since working on active fiber can easily damage the eye.

The fiber optic inspection microscope is a valuable tool for fiber optic technicians due to its ability to facilitate thorough and accurate inspections of fiber optic connectors. By visually inspecting the end-faces of connectors, technicians can ensure that connections are clean, properly aligned, and free from defects that could impair signal transmission. This helps to prevent network downtime, minimize signal loss, and maintain the integrity and reliability of fiber optic links. Additionally, fiber optic inspection microscopes enable technicians to identify potential issues early on, allowing for timely maintenance and repairs before they escalate into larger problems. Overall, the use of a fiber optic inspection microscope is essential for ensuring the quality and performance of fiber optic networks, making it an indispensable tool for technicians working in telecommunications, data centers, and other fiber optic environments.

5. Fiber Identifier

A fiber identifier is a specialized instrument used by fiber optic technicians to non-intrusively detect and identify active fibers within a fiber optic cable without disrupting network traffic. It operates by clamping onto the outside of the cable and detecting the presence of optical signals transmitted through the fiber. The fiber identifier typically features an optical sensor or detector that can distinguish between live and dark fibers based on the intensity of light present in the fiber. When a fiber identifier detects an active signal, it provides visual or audible indicators to alert the technician, along with information about the signal's direction of transmission. This allows technicians to quickly and easily identify live fibers, verify network connectivity, and trace cables in dense or complex fiber optic networks.

Fiber identifiers are valuable tools for fiber optic technicians due to its ability to quickly and accurately identify active fibers within a fiber optic cable. Unlike traditional methods of identifying fibers, which may require physical access to the cable or disruption of network traffic, a fiber identifier enables technicians to perform non-intrusive testing without interrupting network operations. This makes it particularly useful for troubleshooting network outages, verifying network connectivity, and tracing cables in densely populated or complex fiber optic environments. By providing instant feedback about the status of fiber optic cables, a fiber identifier helps technicians to streamline maintenance and repair activities, minimize downtime, and ensure the reliability and performance of critical communications infrastructure.

Conclusion

In conclusion, the test tools outlined above represent the cornerstone of any fiber optic technician's toolkit. From measuring signal power, inspecting connectors, and verifying network connectivity, these essential tools empower technicians to ensure the performance, reliability, and integrity of fiber optic networks. By investing in quality test equipment and mastering their use, fiber optic technicians can confidently tackle the challenges of deploying, maintaining, and optimizing fiber optic infrastructure, ultimately delivering superior network performance and reliability to end-users. Take a look at our catalog of test equipment to get the most efficient and reliable tools for the field!

Comments

Login or Register to post comments.