Basic Hand Tools for Fiber Optic Technicians

Basic Hand Tools for Fiber Optic Technicians

If you were to ask any seasoned fiber optic technician for advice on the basic fiber optic hand tools every entry-level technician needs to have in their toolbox, you will get an endless list that will differ (sometimes greatly) from one person to another. In this post, we’ll break down and provide a general overview on which fiber optic hand tools should be the basic tools in every technician's toolbox.

Fiber Optic Hand Tools

As you already know, tools for installing, terminating, or repairing fiber optic cabling are different from what is used on other kinds of cabling. These tools are specifically designed to allow a technician to manipulate optic fibers while not impacting the fiber in any negative manner.

The Tools You Need to Get Started

Believe it or not, a starter fiber optic cabling toolbox does not have to include large numbers of tools. The primary things to keep in mind while selecting these tools are functionality, reliability, and versatility. These three criteria will help you select the right ones.

A few considerations before seeking out your tools. Sean Burridge, fiber technician, and apprentice electrician says selecting tools as a novice comes down to, “trial and error.” He suggests doing research into, “the brands that provide the best warranties on their products... then find the quality you like and find the brands that you like.” Lastly, he recommends making an investment in your tools.

The Collection of Fiber Optic Hand Tools Should Include the Following:

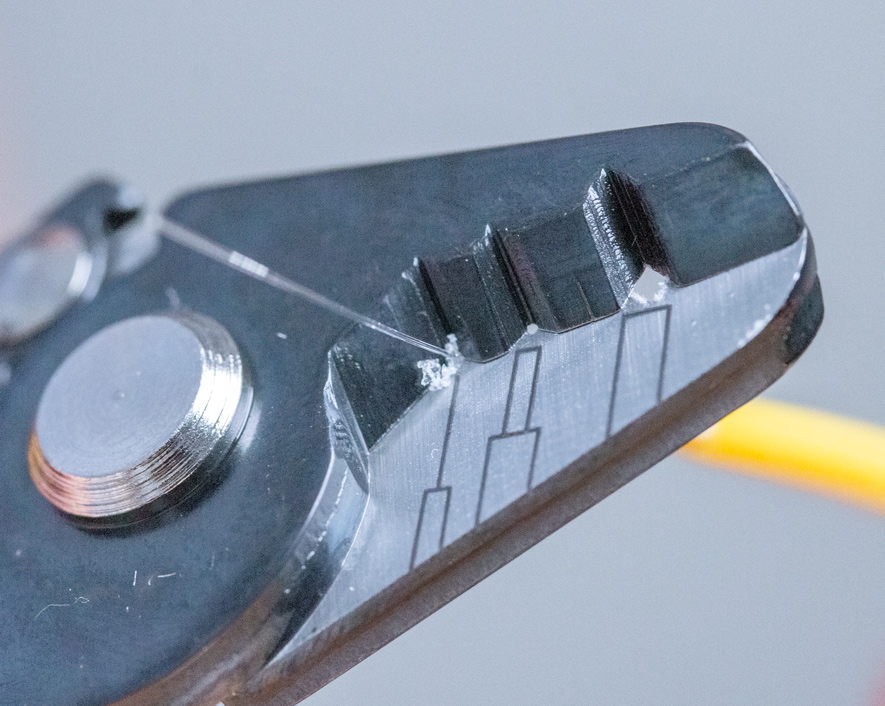

Fiber Strippers- The most effective strippers will allow a technician to peel back the layers on fiber optic cabling to neatly access the optical fiber. Most fiber optic strippers feature multiple holes of different sizes. The popular Jonard Tools JIC-375, Fiber Optic Stripper, Three Hole, for example, strips fiber optic jackets from 1.6mm to 3.0mm in diameter. The first hole strips them down to the 600–900-micron buffer coating. The second hole on the tool strips off the buffer coating, exposing the acrylate coating on the optical fiber. Lastly, the third hole strips the acrylate coating exposing the glass fiber without causing any damage to the fiber.

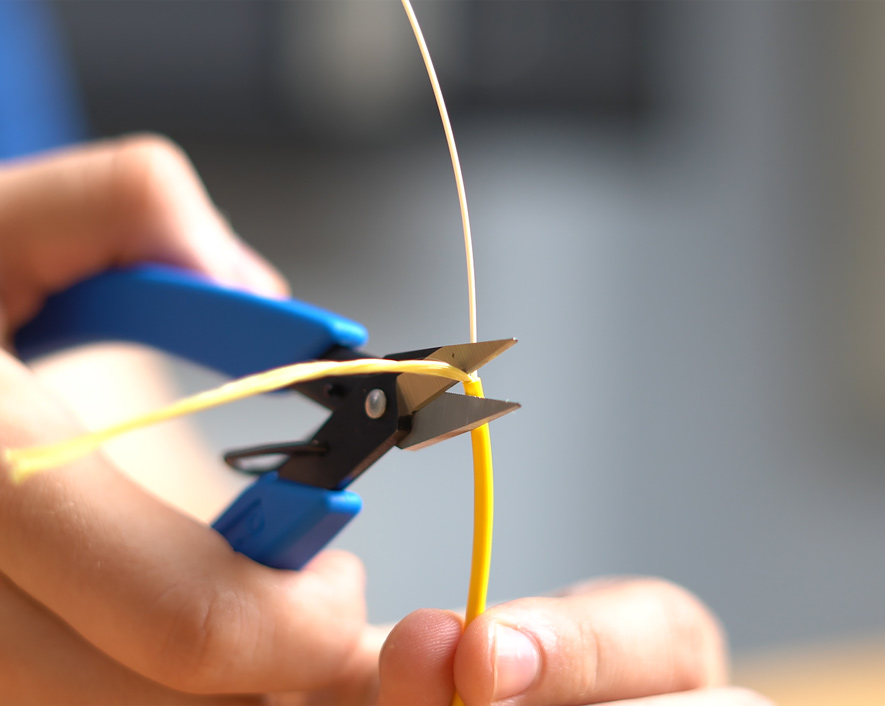

Kevlar® Cutters - These specialized scissors/sheers are intended to cut through Kevlar®, a heat-resistant and lightweight fiber that is renowned for its high tensile strength. Kevlar® cutters have sharp, serrated blades, that neatly cut through these fine and strong fibers. Several Kevlar Cutters that warrant high consideration when cutting thru fiber include:

The JIC-190 Flush Cut Kevlar Cutters. These Kevlar® cutters have thin-nose jaws and are designed to cut Kevlar® cabling insulation, tape, cable ties and other materials flush to the surface. The thin-nose provides easy access into tight places and allows for flush cutting of Kevlar® to the fiber jacket.

The JIC-186 Wire & Kevlar Cutting Shears. The high carbon stainless steel, serrated blades are heat-treated to HRC 58-60 for longer life and durability, have handles made of dual component nylon and Santoprene™ material and are ergonomically designed for superior comfort and long-term durability.

The KWC Multi-function Kevlar® & Wire Cutting Shears, 7”. These shears are the ultimate scissors of choice for the fiber technician or electrician. They are designed with serrated blades, large cutting notch, non-insulated terminal crimpers, and spring-loaded handles.

Midspan Tools – Midspan tools like Jonard’s patented line of Mid Span Slitting and Ringing tools are designed to provide easy access to optical fibers in outer jackets and loose buffer tubes. These tools eliminate the need to use something like an electrician’s knife, or a utility knife to shave away the layers to access the glass fiber.

Cleaning Supplies

General cleaning wipes are always a good idea to keep close by to make sure your workspace is free of dust and debris. But these are not the only ones.

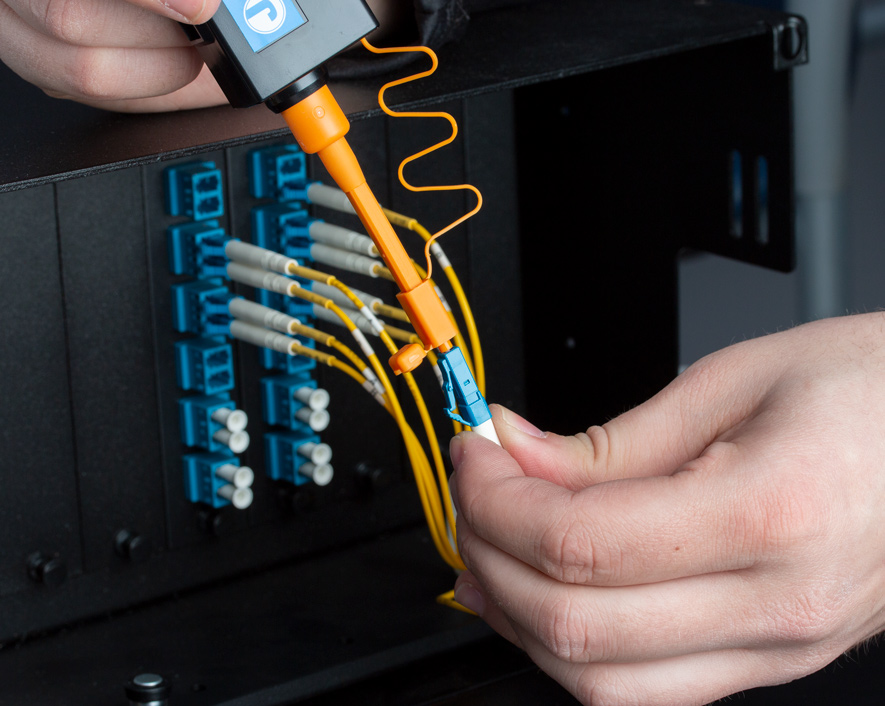

Fiber cleaners. While these seem like a no-brainer, this list wouldn’t be complete if we didn’t mention them. Regardless of how careful or neat you think you are while working with fiber optic cabling, it’s crucial to remember to keep fiber ends and connectors clean. Specialized lint-free fiber optic cleaning wipes and cleaning solutions will help eliminate oils from fingers or dust from surfaces. These also come in handy when working with gel-filled cables.

Fiber Connector Cleaners like our, FCC-120, FCC-250, and FCC-125 are excellent choices as well since they will keep end-face ferrules clean.

Other Considerations

So far, we’ve provided a list of suggested fiber tools, however, there are several tools that should be kept handy but aren’t intended to be used exclusively on fiber. These include pliers, blade sharpeners, and can wrenches to access pedestals or pole closures.

“I think it’s also important to have a good knife in hand, preferably something with a hook blade,” says Sean Burridge, fiber technician and apprentice electrician. “I also suggest keeping nut drivers, flat head screwdrivers, needle nose pliers, and linemen pliers in any toolbox.”

Selecting the Right Tools

Over the decades, fiber optic cabling has been evolving to allow for greater bandwidth and signal quality. Along with this progress, the marketplace has seen an increase in hand tools for fiber optic cabling. So how do you know what to look for?

A common misconception is that reliable tools for fiber optic cabling will come with a steep price tag. While it’s true that some tools can be expensive, the primary determining factor should be the quality of the tool. Poorly made or lower-quality tools will have to be replaced more often and will end up costing more in the long run.

“There’s an old saying that goes, ‘cheap is expensive,’” says Francisco Moreno, fiber optic specialist with Academia PON. “In my courses, I like to make a showroom with a lot of fiber optic tools, and I like to place lower quality (often inexpensive tools), next to high-quality ones so that the technicians learn to distinguish between them… They quickly learn that the quality of the materials of the tools that makes all the difference.”

Maintenance

Now that you have a great starter toolbox, make sure you get acquainted with them and make sure you understand what each tool can do, and how they are supposed to function. Any tool can be compromised if not cared for properly.

Additionally, Francisco Moreno states that “Proper maintenance of a tool can prolong the life of a hand tool. I always suggest keeping tools clean and removing debris from the tools before and after using them. Maintenance is key. Treat your tools good, they’ll treat you good. I like to use hand wipes to clean them off and if they get wet while you’re working, soak them in some WD-40 and then dry them off before putting them away.”

Check blade edges. Even the sharpest blade can become dull after a certain amount of time and repeated use. Replace them when needed.

When should I upgrade/replace tools?

In short, when the tool or product is no longer performing optimally, or they come to the end of their indicated “lifespan.” For example, our fiber cleaners (enter part numbers) will last for approximately 800 clicks, or the blades in some of our Mid Span Slit and Ring Tools will last for an average of 5,000 cuts and slits.

Precision tools like Kevlar cutters or fiber strippers should be replaced as soon as you notice any degradation in performance. For example, taking more than one cut to cut the Kevlar, or resulting in a rough cut. As for fiber strippers, a common sign that it’s time to replace them is when they don’t remove the acrylate coating, as well as when the fibers inside the cabling begin to break more often than before.

When you reach this point, reach out to your tool manufacturer. Some will offer special discounts for replacement tools, or as with Jonard, most of our hand tools are backed with a Made for Life®, guaranteed for life policy.

About Jonard Tools:

Founded in 1958, Jonard Tools® manufactures tools for the Telecom, CATV, Fiber Optic, Home Automation, Security & Alarm, and Electrical markets. Jonard Tools designs and engineers patented products by utilizing customer partnerships to create innovative solutions for industry needs. New tools are released each month and are all Made For Life® with lifetime warranties. Through quality and innovation Jonard aims to move the industry forward and connect the world.

Website: https://jonard.com/

Comments

Login or Register to post comments.