Fiber Optic Strippers. A Love Story between Engineers and Strippers.

Fiber Optic Strippers. A Love Story between Engineers and Strippers.

To start you might ask yourself – love story? Yes, as an engineer this is the kind of stuff I love to dirty my hands with. I love my wife too, but fiber optic strippers …c’mon.

There are three main ways to strip an optic fiber: chemical, mechanical and thermo mechanical.

If you ask me, the need for chemical stripping is a result of someone having too much time on their hands and needing to justify their position and work. It is not practical and so many other better options already exist. Picture this; you must dip the fiber into an acid bath to dissolve the coating and expose the optical fiber. You have no choice when the coating has high adhesion and applying heat does nothing to decrease the adhesion. This is going to come out of left field, but I happen to love chocolate the way Willy Wonka loves chocolate. Now imagine trying to remove Willy from his chocolate factory after a new batch of chocolate has been cooked – impossible without a superhuman effort, just like those chemical coated fiber cables - really tough.

Now if you’re like me, your preference would be mechanical stripping. Just the thought of it gets me going. It’s a much more common approach, easily performed in any work environment and is the most widely accepted means of stripping fiber optic cable. The key advantages are ease of use and low investment cost (Many fiber stripping tools can be purchased for less than thirty dollars). No budget buster here. Most of these tools are hinged and look similar to a scissor or a small plier.

Tools may come with a single hole for removing the acrylate coating such as the Jonard JIC-125, or multiple holes so you can strip the cable jacket, buffer coating and acrylate coating, all in one tool. The Jonard JIC-375 is one example of a three-hole fiber stripping tool. To use simply open the tool, place the fiber over the stripping hole, squeeze the jaws and slide the tool down the length of the fiber. Some brands other than Jonard Tools may require a special technique such as tilting the stripper on an angle to get the best strip.

There are disadvantages to mechanical stripping. Number one is consistency in stripping, and number two is reducing the stress on the fiber caused by the mechanical nature of the stripping process. Another problem is human factor and the possibility of nicking and scratching the fiber…a No No. Many mechanical stripping applications are performed for prepping a fiber to be fitted with a connector. Here the concern may not be as high as when the cable is stripped for other uses where the fiber is exposed.

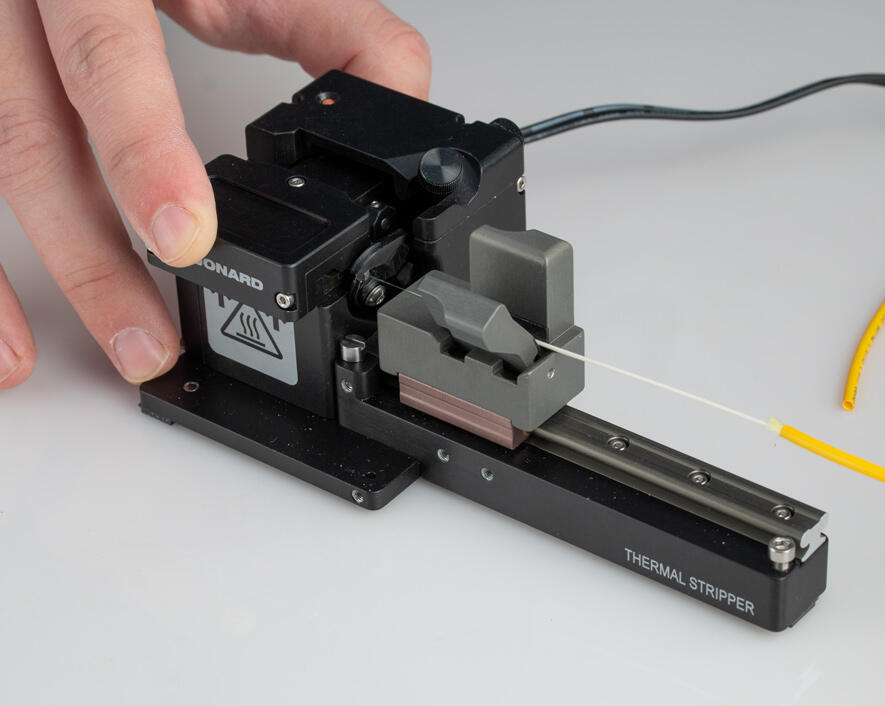

Thermo mechanical strippers take mechanical stripping to the next level by introducing heat to the area being stripped. The heat softens the coating covering the fiber and helps reduce the adhesion between the fiber and the coating. This reduction in adhesion also reduces the stress on the fiber during the stripping process. The heating cycle is helpful on some hard to remove coatings other than typical acrylate coatings. Some thermo mechanical stripper designs such as the Jonard TSFB-125 and TSAB-40 reduce human interaction with the fiber and provide a high strength stripped fiber where the process is repeatable with more consistent results when compared to a standard mechanically stripped fiber. These strippers are significantly more costly than regular mechanical strippers but provide greater flexibility and a level of repeatability that cannot be matched with a mechanical stripper.

As you can see Chemical stripping is best used in the lab as it has minimal application in the field. Mechanical stripping is the general standard most widely used but has some drawbacks in terms of repeatability and tensile strength. Thermo-mechanical stripping solves the issues of mechanical stripping but at a cost. If you are stripping a fiber to apply a connector a mechanical stripper is most probably your best choice. If you are stripping fiber for a fusion splice a thermal stripper is a better choice. Don’t you just love it?

Written By Rich Gerszberg, CEO of Jonard Tools

About Jonard Tools:

Founded in 1958, Jonard Tools® manufactures tools for the Telecom, CATV, Fiber Optic, Home Automation, Security & Alarm, and Electrical markets. Jonard Tools designs and engineers patented products by utilizing customer partnerships to create innovative solutions for industry needs. New tools are released each month and are all Made For Life® with lifetime warranties. Through quality and innovation Jonard aims to move the industry forward and connect the world.

Website: https://jonard.com/

Comments

Login or Register to post comments.